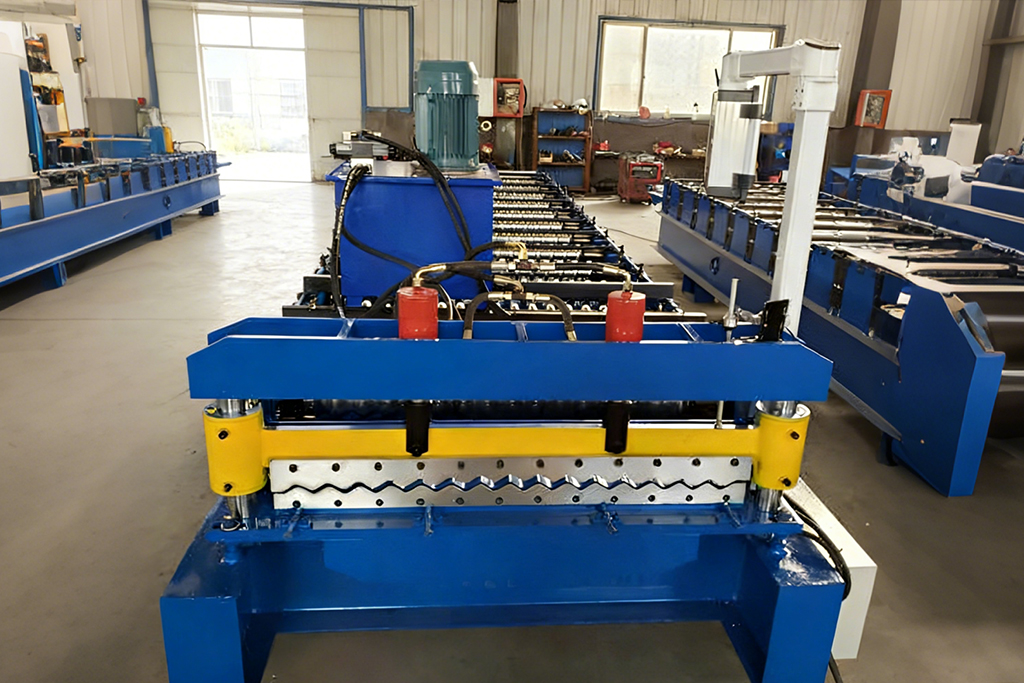

Corrugated roofing sheet roll forming machine

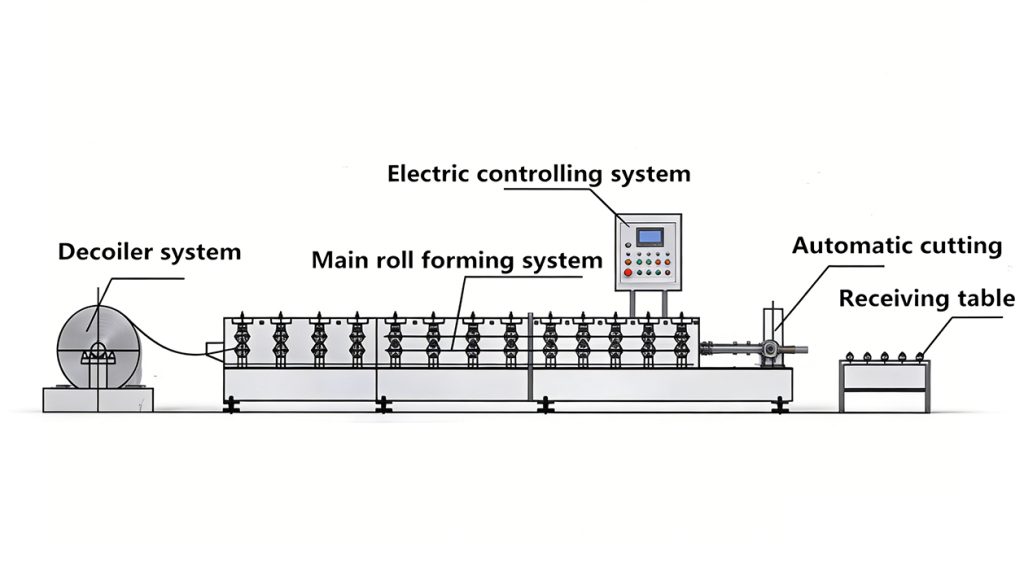

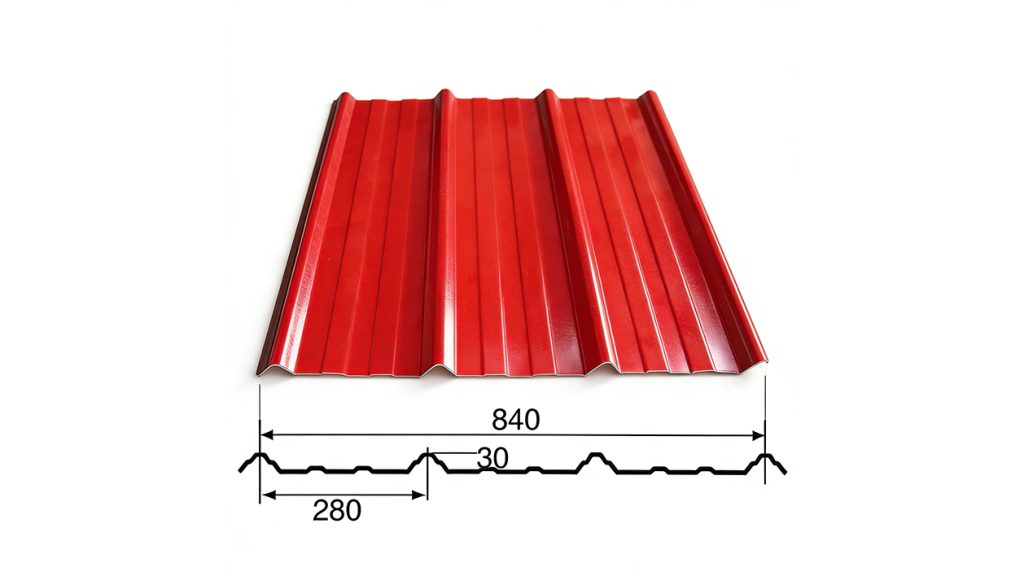

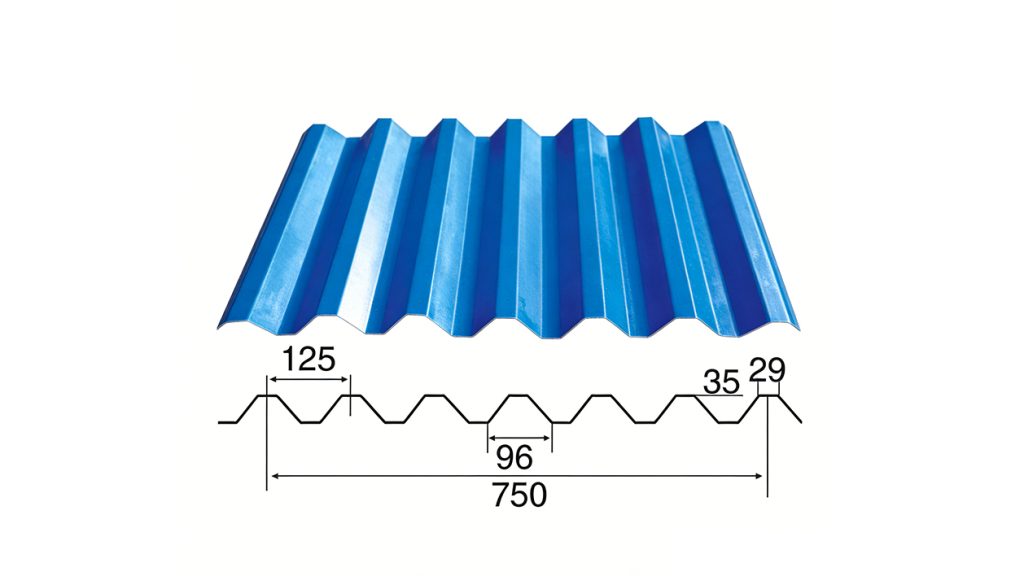

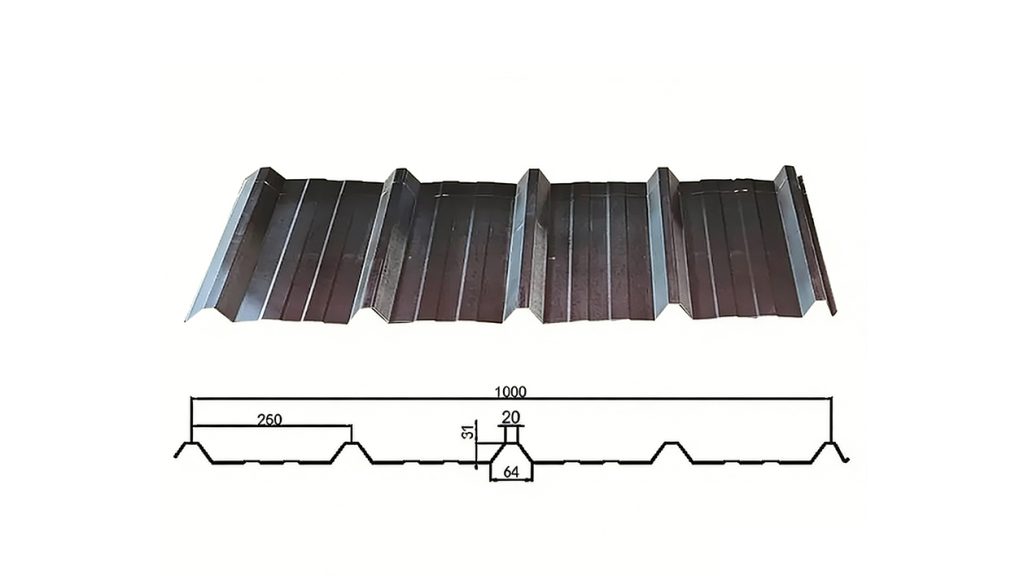

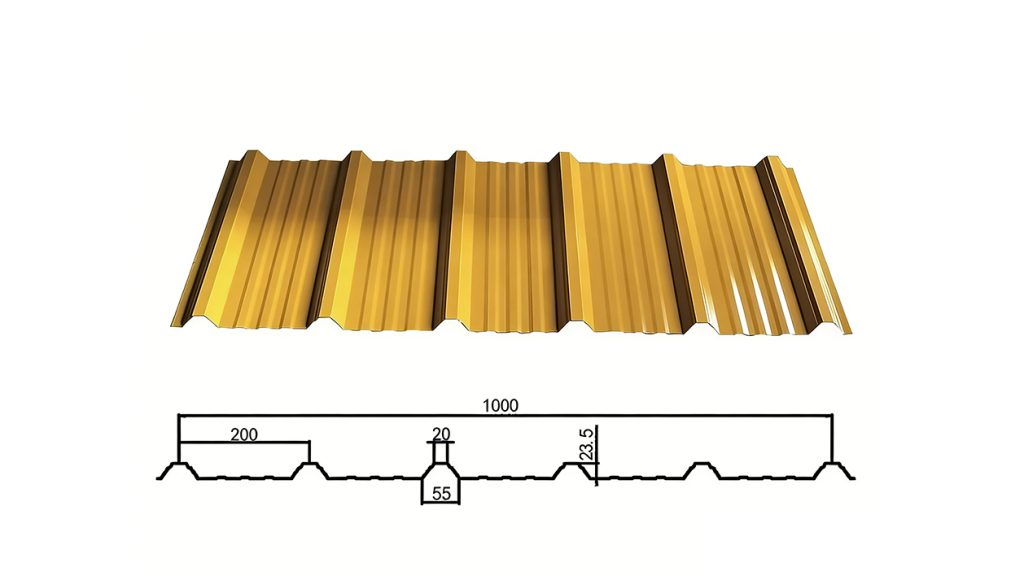

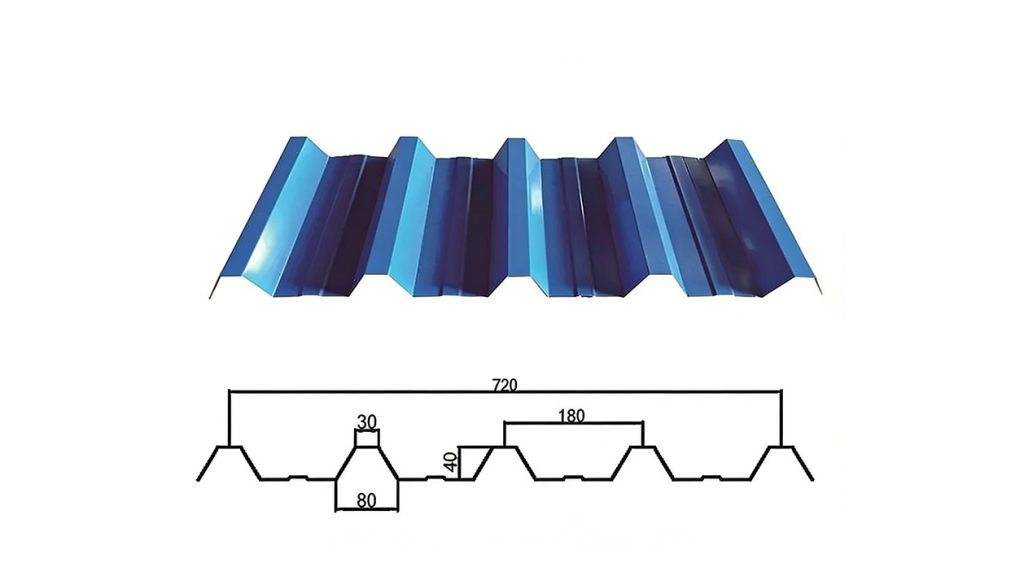

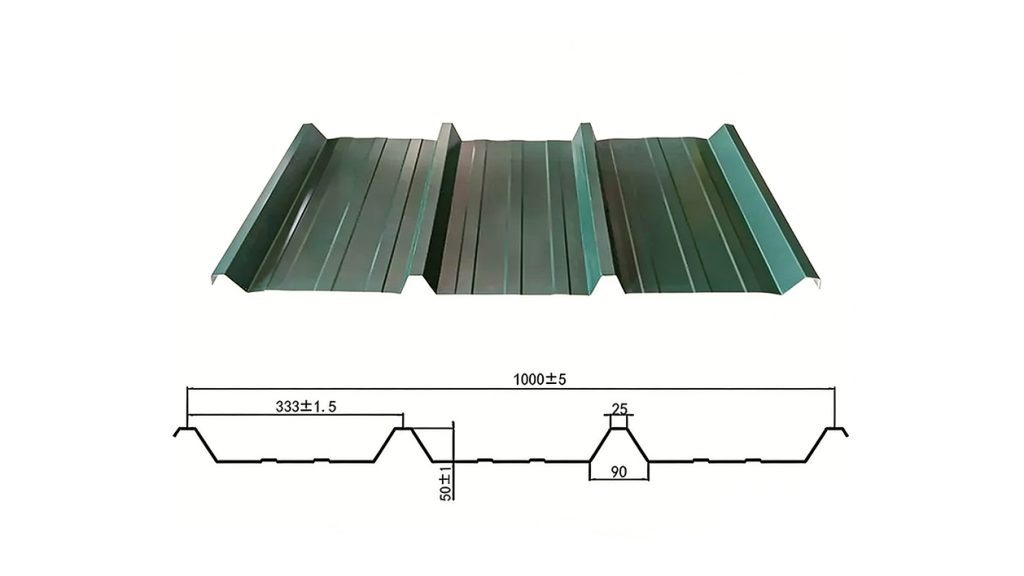

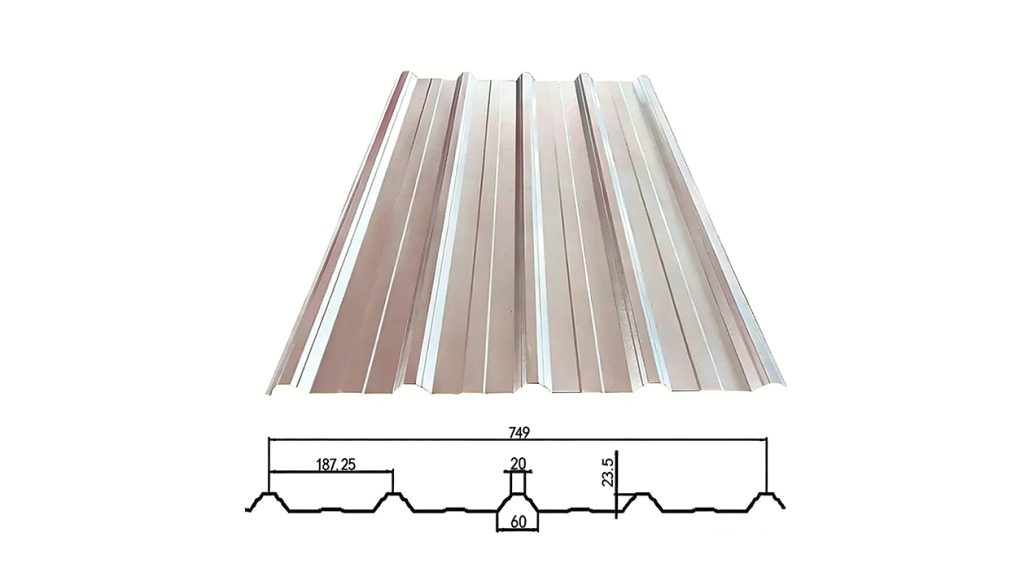

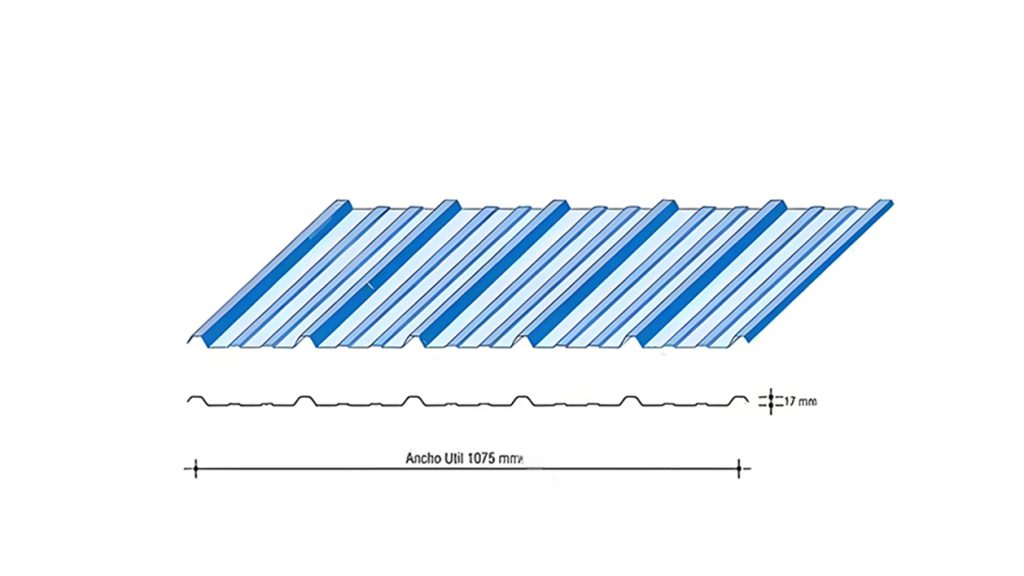

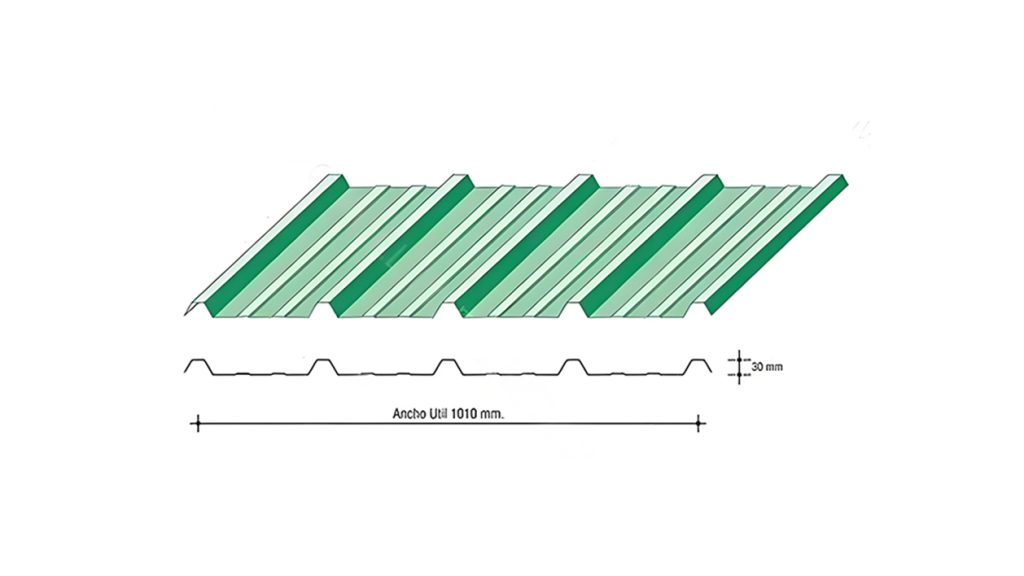

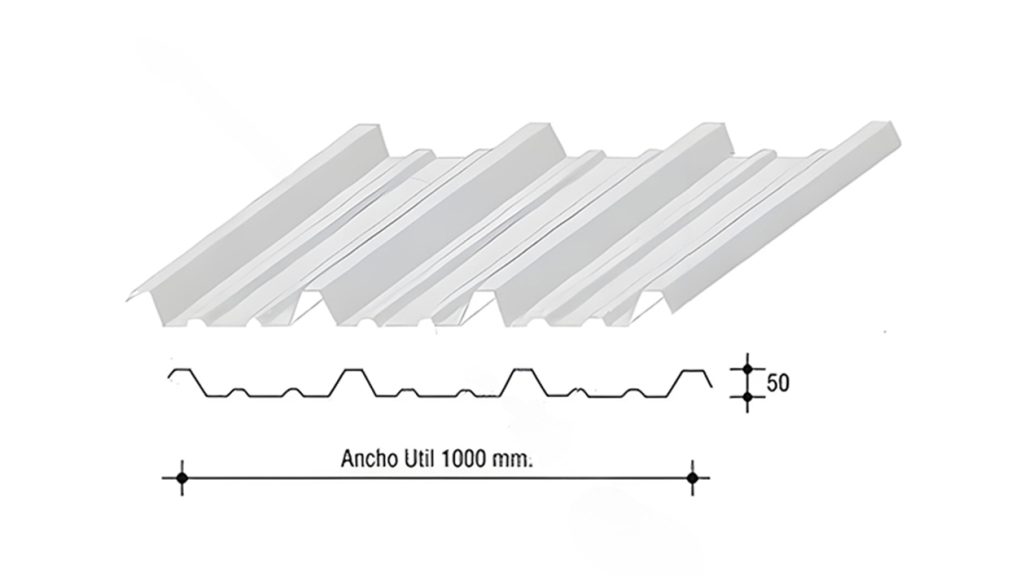

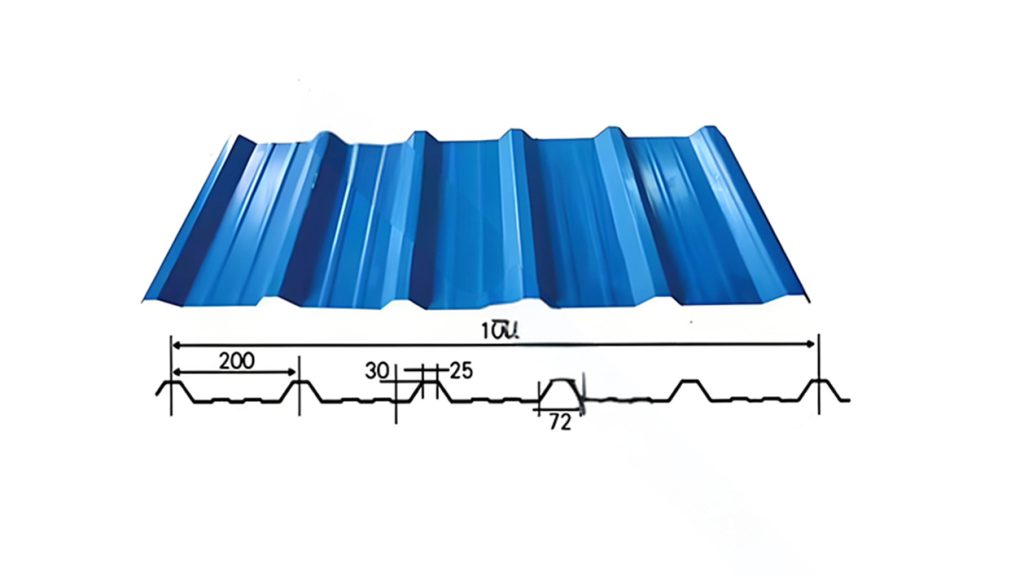

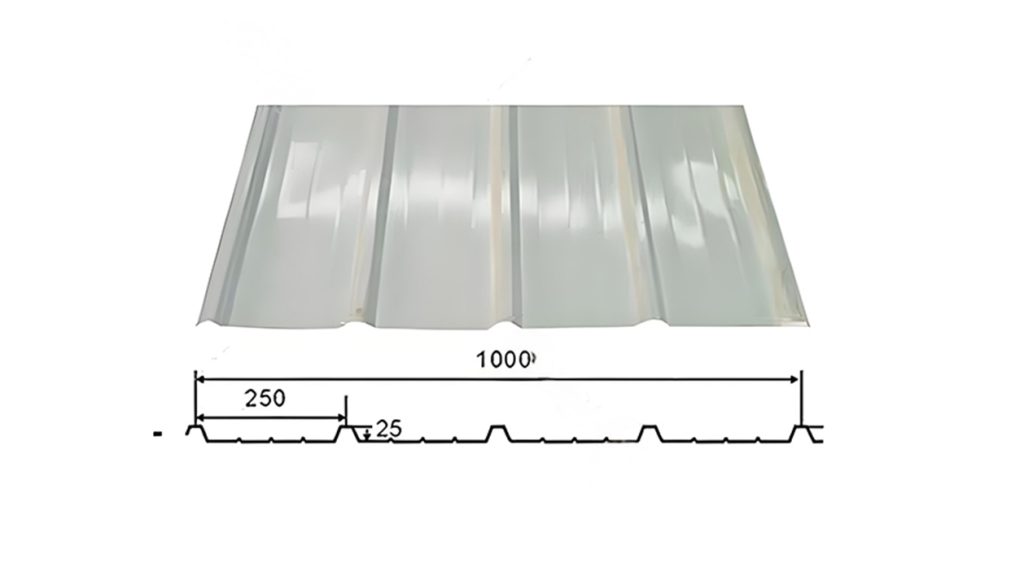

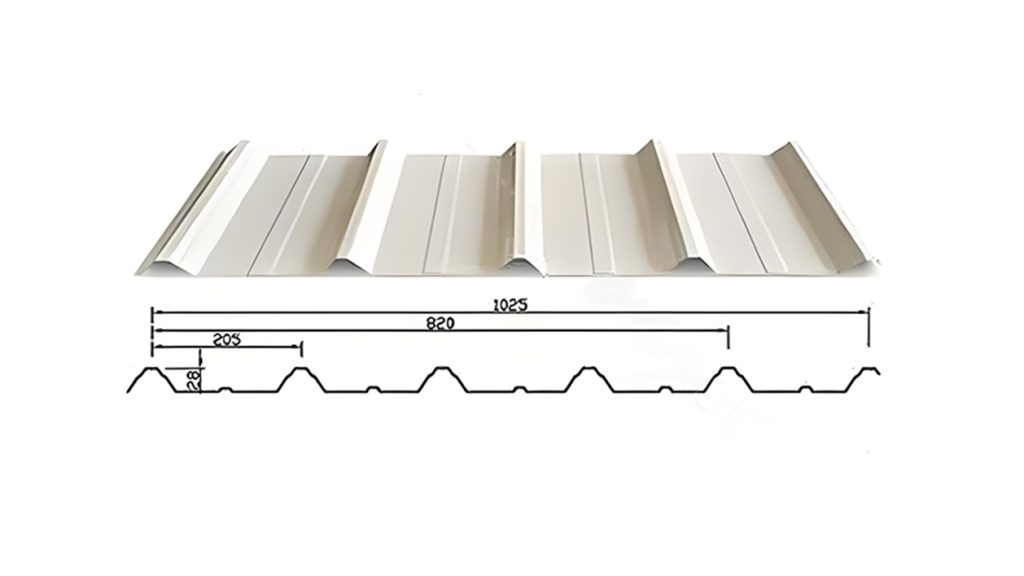

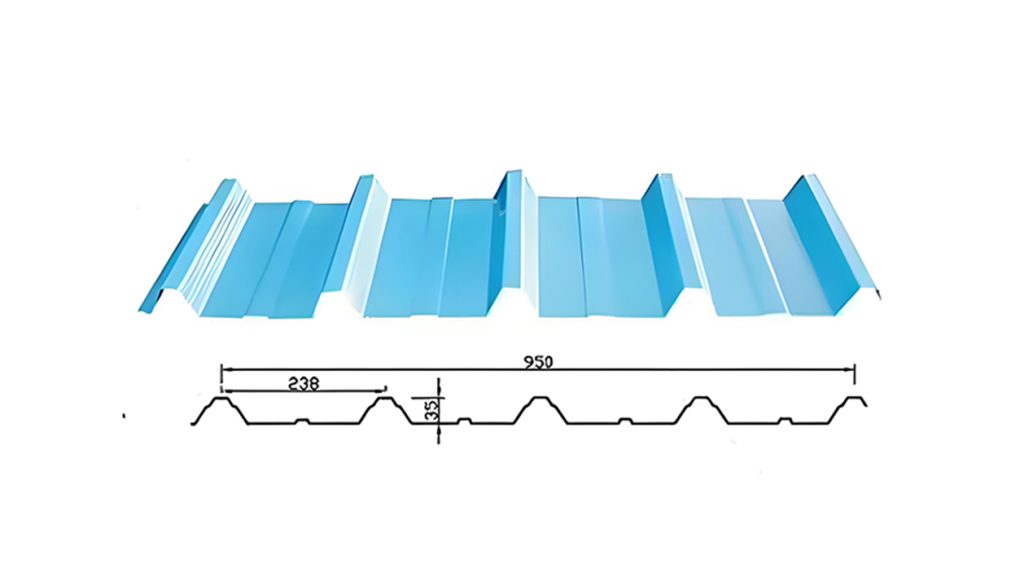

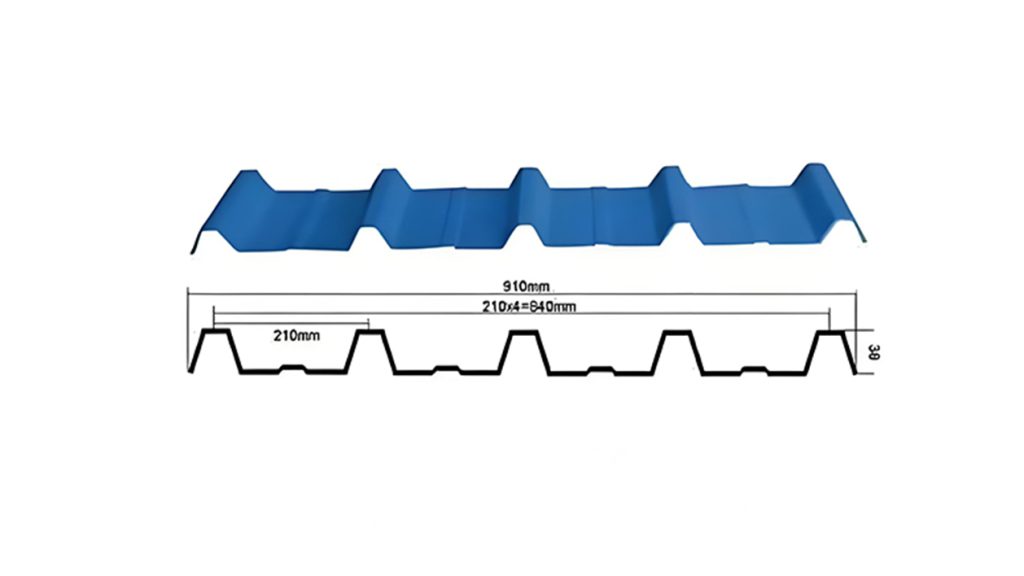

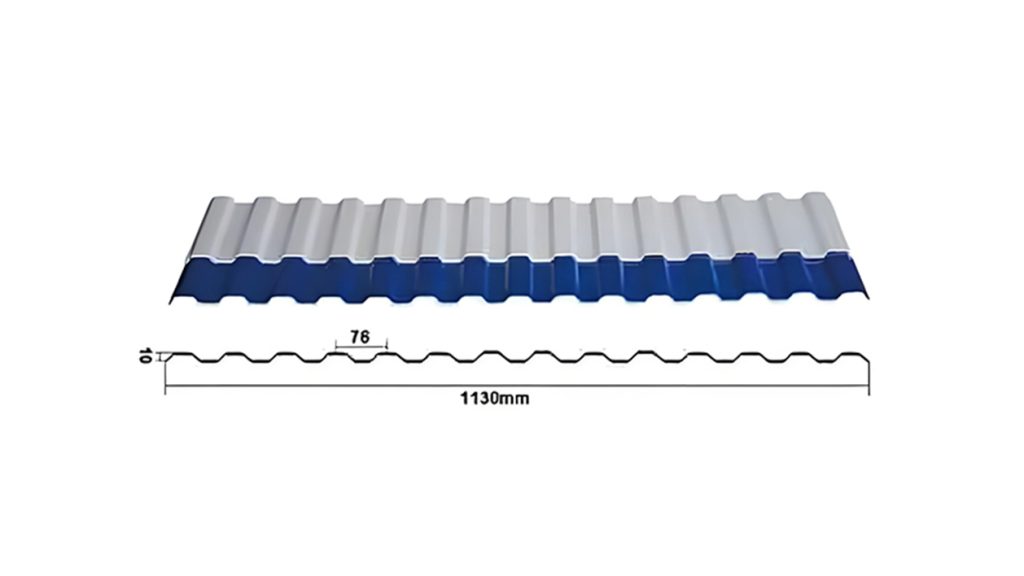

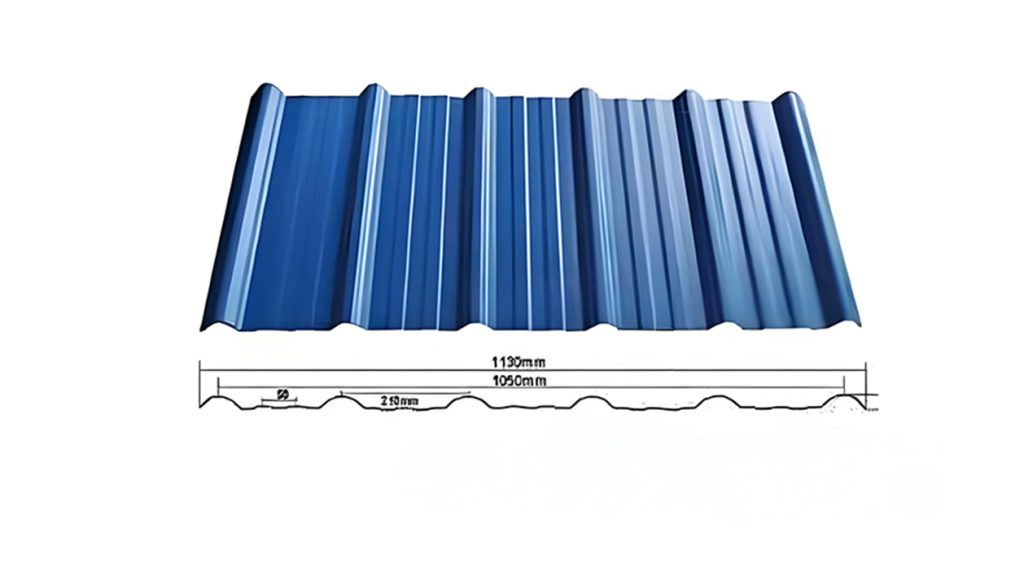

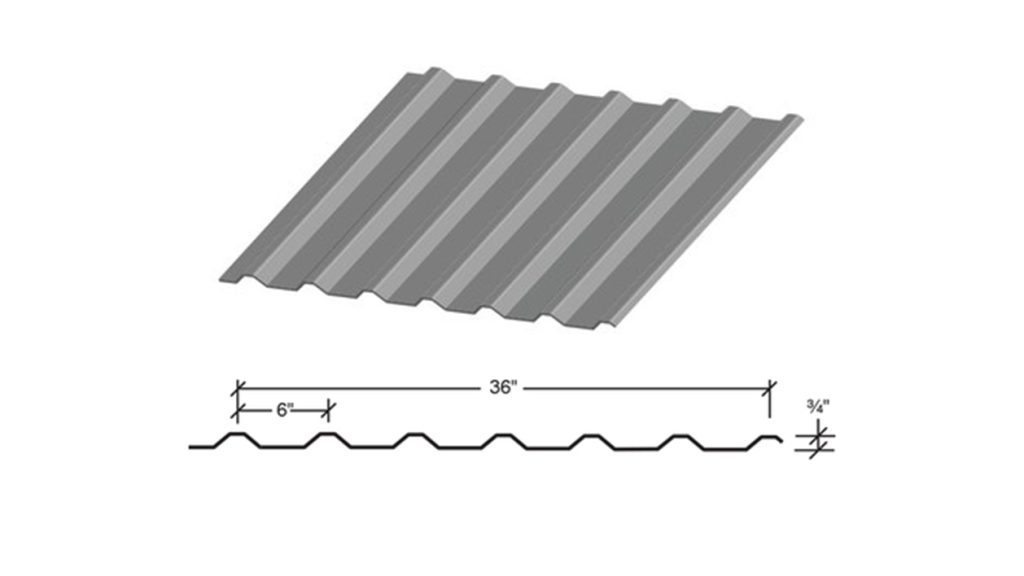

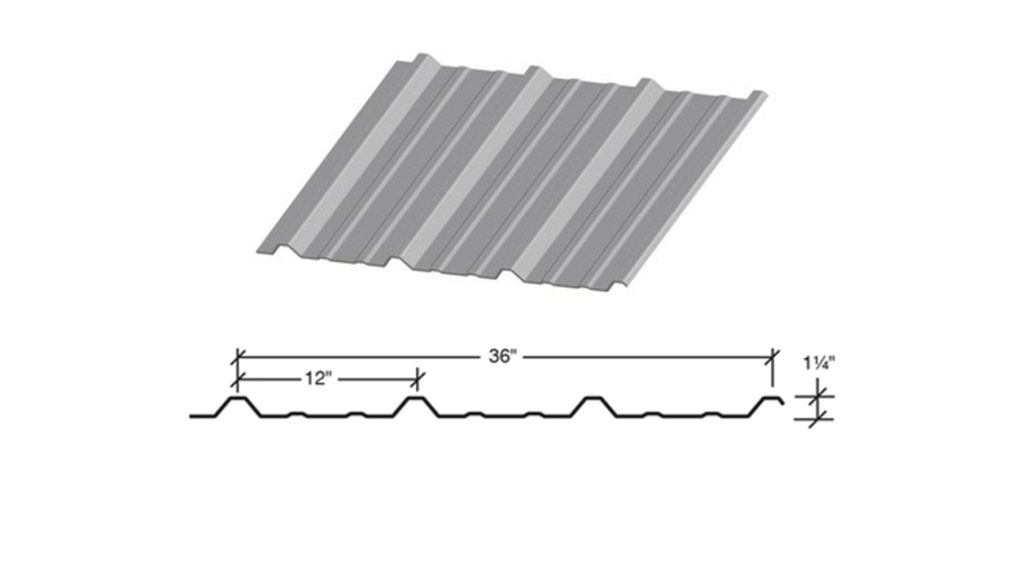

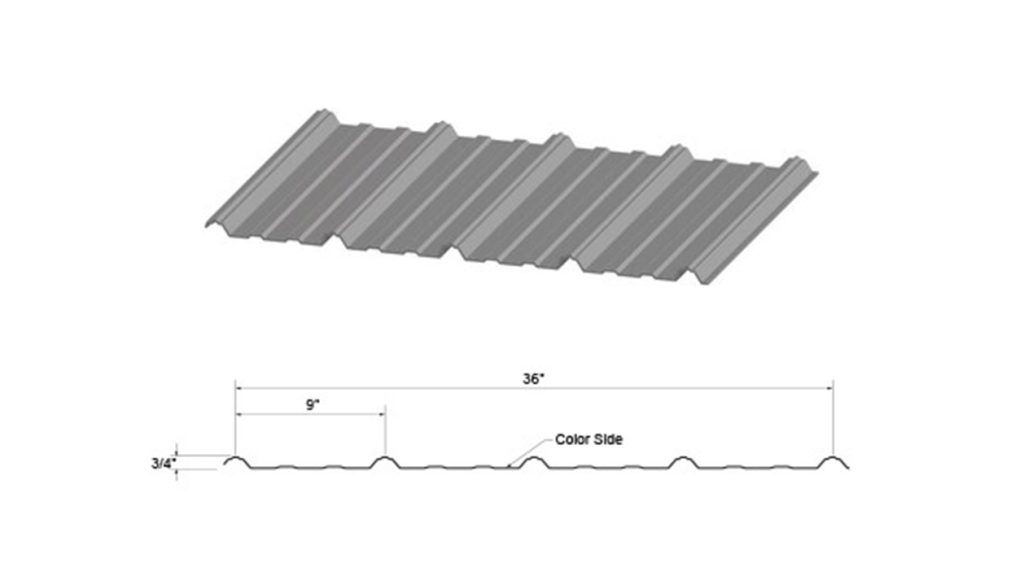

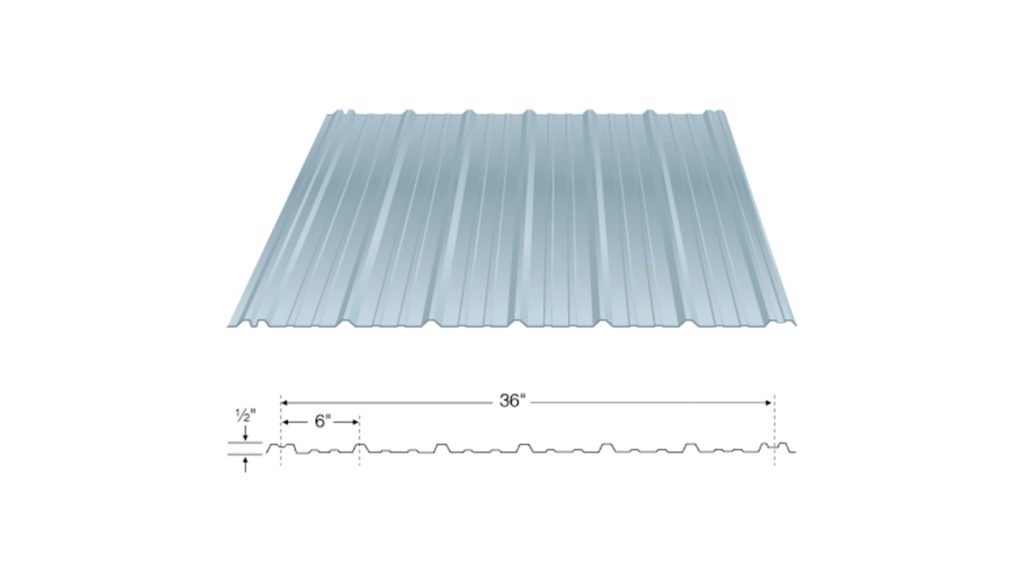

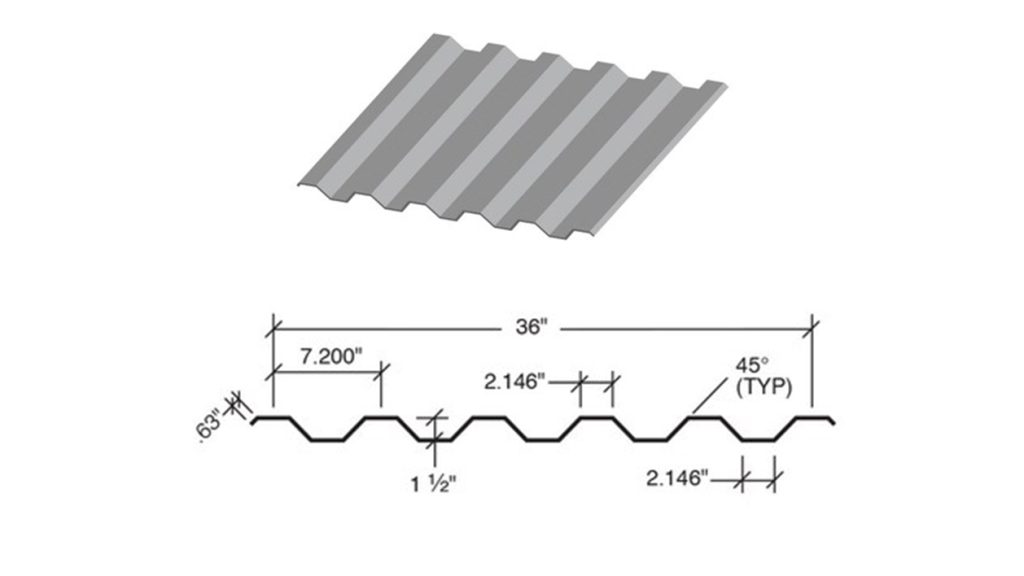

A corrugated roofing sheet roll forming machine is a highly automated continuous production line. It uses a series of precisely designed forming rollers to continuously cold-bend metal coils (such as galvanized steel sheets, color-coated sheets, and aluminum-zinc-magnesium sheets) at room temperature, ultimately producing roofing or wall panels with specific corrugated cross-sections (such as classic 820, 840, 900, and angle-seam types).

Corrugated roofing sheet roll forming machine achieves a one-stop, high-efficiency, and high-precision conversion from raw materials to finished products. It is an indispensable core production equipment in the manufacturing of modern metal building envelope systems, directly affecting the waterproofing performance, structural strength, and aesthetic appearance of the final building.

-1.png)